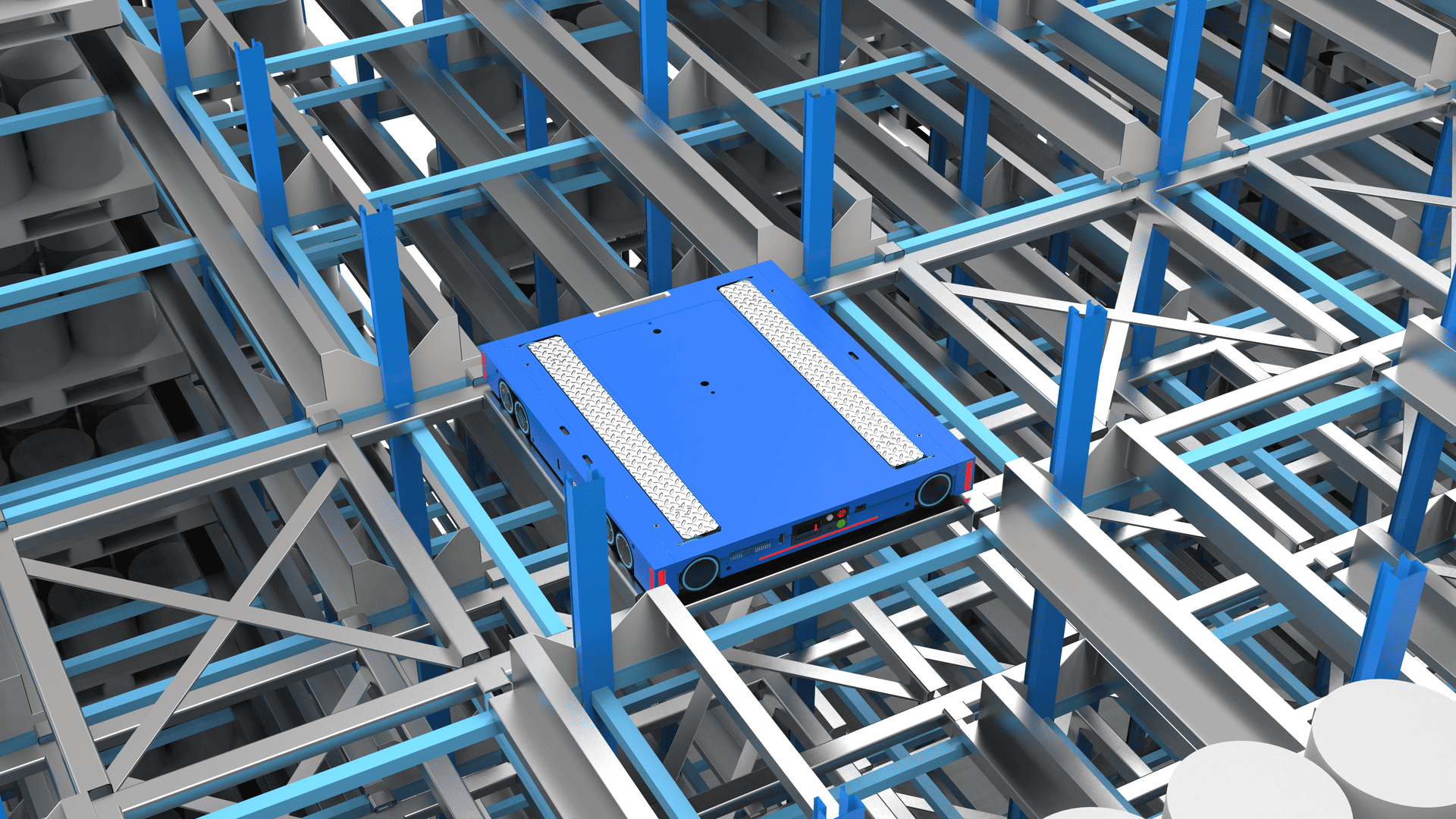

The Four-Way Shuttle System is a high-density automated storage solution designed for efficient palletized goods management. It is ideal for industries with a limited number of SKUs (Stock Keeping Units) and operations that require storage and retrieval by lot or batch. This system is particularly suitable for sectors such as food & beverage, chemicals, and logistics services, enhancing space utilization and operational efficiency.

This system utilizes advanced movement technology, allowing pallets to travel in four directions: left-right, front-back, and up-down. This flexibility enables optimized routing within the storage area, maximizing horizontal space utilization. Compared to traditional Automated Storage and Retrieval Systems (ASRS), the Four-Way Shuttle System increases storage density by approximately 5-10%, making it a highly efficient solution for high-density warehousing.

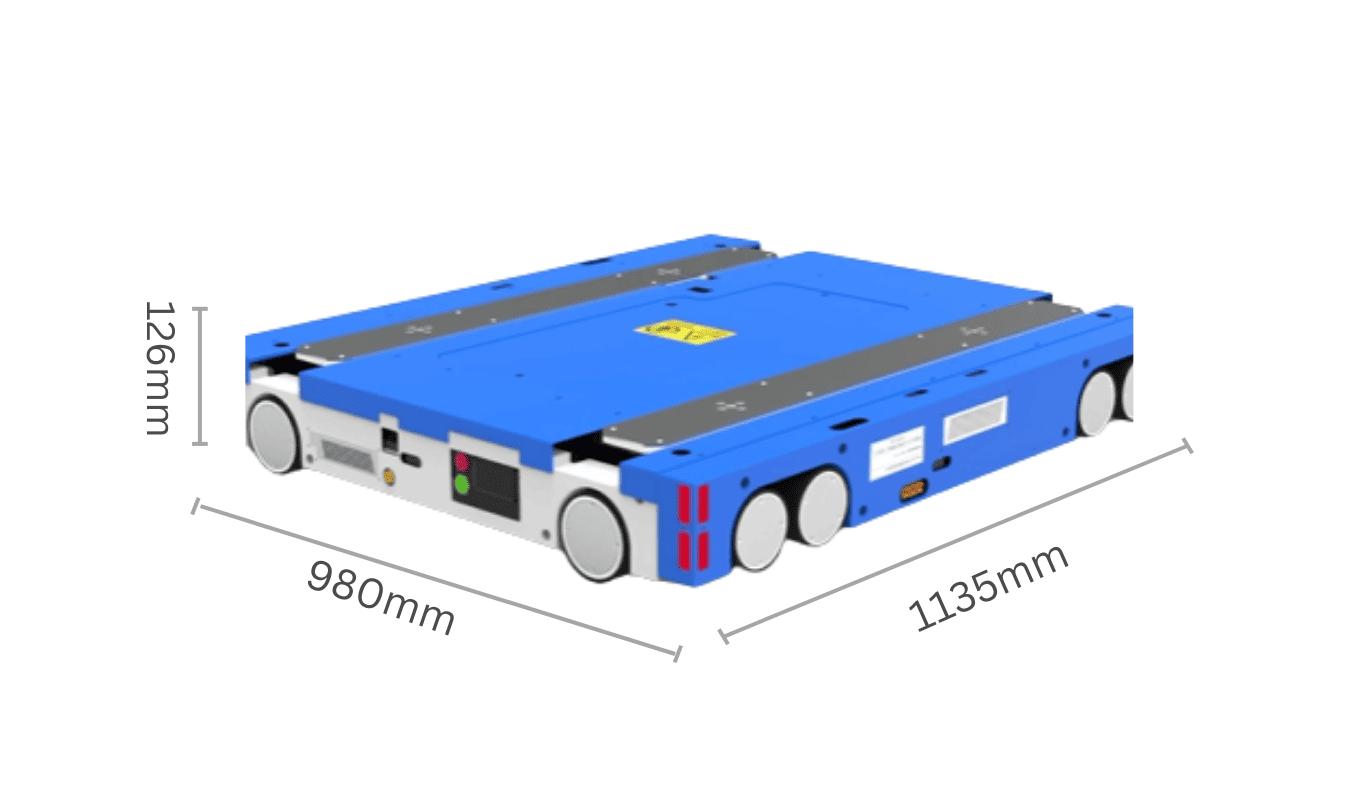

Pallet Transport Robot

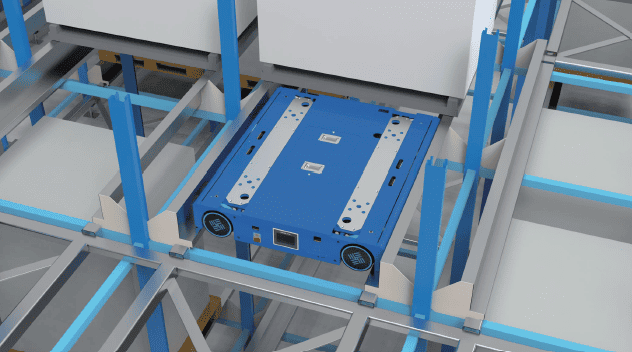

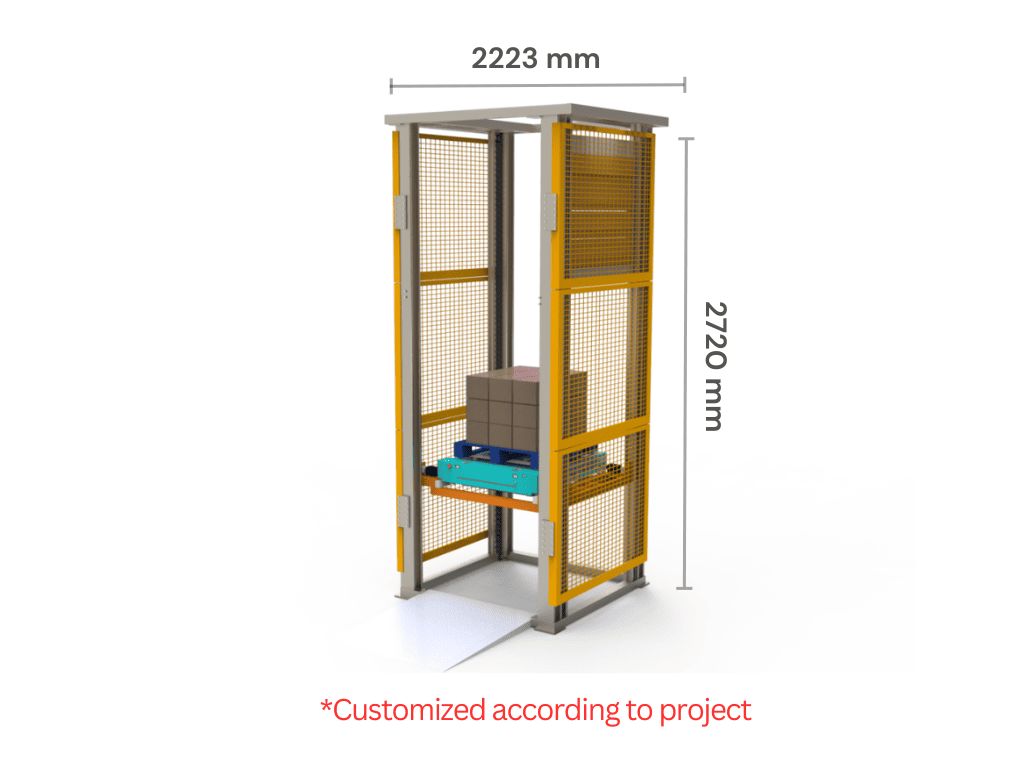

Vertical Lift Transport Robot

The system increases storage capacity by making the most of the available warehouse space and height, even in limited areas.

Easily extend racking and storage tracks in the future without disrupting system operations during installation.

The system fully integrates with WMS or WCS , ensuring smooth operation. It supports wireless connectivity for real-time, seamless control and monitoring.

Shuttle carts can operate independently. If one unit fails, others can take over its function. Additionally, they have a backup power system to help reduce downtime.

Comparison Between

We provide complete warehouse management solutions tailored to every business's needs.

คลังสินค้าอัตโนมัติ (ASRS - Automated Storage

& Retrieval System)

รีวิวผู้ใช้งานระบบ ASRS Warehousing Technology

ในประเทศไทย - WGC x AEI Solution

AGV Robot x ASRS THAILAND