The system supports comprehensive warehouse operations by directly and automatically delivering items from storage areas to the workstations of pickers according to order lists. It controls and manages workflows using both software programs and scanning functions, ensuring efficient and accurate order fulfillment.

The “Good to Person” solution enhances operational efficiency and accuracy by streamlining processes and reducing potential errors caused by various factors. It minimizes the need for employees to walk around or operate forklifts in the storage area to retrieve items, as goods are delivered directly to them. This not only saves space in the warehouse but also improves safety by reducing the risk of injuries from lifting heavy items.

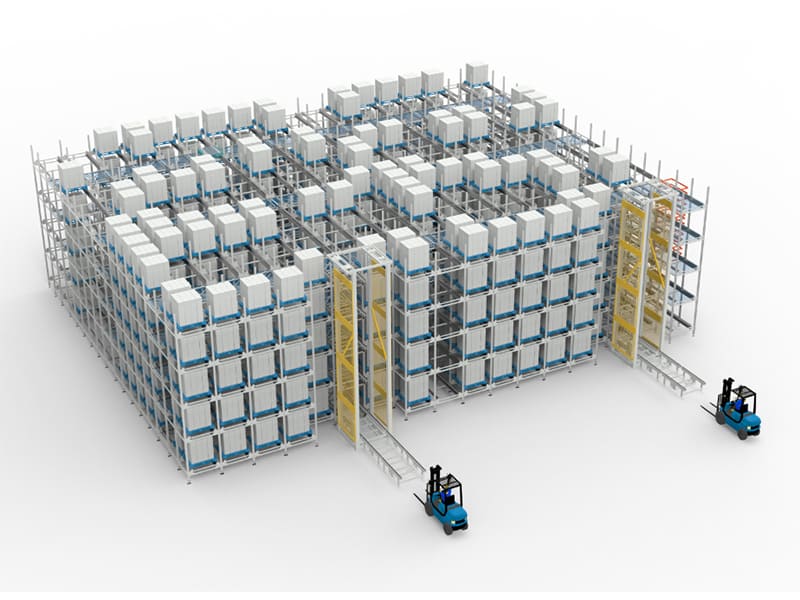

Space Savings in the Warehouse

With the Good to Person solution, warehouse space is optimized as employees no longer need to walk around or operate forklifts within the storage area. This efficient system brings items directly to the picking stations, reducing the need for extensive aisles and increasing usable storage capacity.

High-Density Storage

High-density storage areas can be optimized by leveraging vertical space, thereby reducing the overall storage footprint required. By utilizing vertical shelving and stacking systems, youn can significantly increase storage efficiency and maximize the use of available warehouse space.

Reduce Product Travel Time

The Good to Person solution minimizes the time spent moving goods by directly bringing items to the picking stations. This reduces the need for employees to travel to various locations within the warehouse, thereby decreasing the likelihood of errors associated with manual item retrieval and enhancing overall operational efficiency.

Flexible and Cost-Effective

The Good to Person solution offers flexibility and cost-effectiveness, allowing for easy expansion and customization of warehouse operations as your business grows and evolves. This adaptability ensures that the system can be scaled and adjusted to meet future demands without significant additional investment or disruption.

Enhance Employee Safety

The Good to Person solution improves employee safety by reducing the need for heavy lifting and minimizing the risk of accidents within the warehouse. By automating the retrieval and delivery of goods to picking stations, it lessens the physical strain on workers and decreases the likelihood of injuries and accidents commonly associated with manual handling and movement in the warehouse environment.

Reduce Human Error

The Good to Person solution minimizes the chances of human errors, such as picking the wrong items. By automating the retrieval process and using accurate systems for item selection, it enhances picking accuracy and improves customer satisfaction. This increased precision ensures that orders are fulfilled correctly, leading to better service and fewer returns or complaints.

We are leading Expert in Integrated Automated Warehouse Systems ,We design, install, and manage automation projects with precision and integrity — from consultation to after-sales service. No shortcuts. No compromises. Just quality, transparency, and long-term reliability

“If you’re looking for true value, transparent pricing, and long-term reliability Contact me ! you can trust.”

We are a System Integrator team importing world-class machinery from leading global brands, with over 10 years of experience in Automated Storage and Retrieval Systems (AS/RS). Our one-stop service is delivered by skilled Thai engineers and programmers specializing in WCS/WMS software and PLC hardware. Every project is supervised by our in-house engineering team ensuring seamless integration, precision, and reliability from start to finish.

Automated Storage and Retrieval System (AS/RS) consists of racking structures designed for both horizontal and vertical storage, with multiple tiers to maximize space utilization. The system is operated by automated cranes or machines (SRM) that handle…

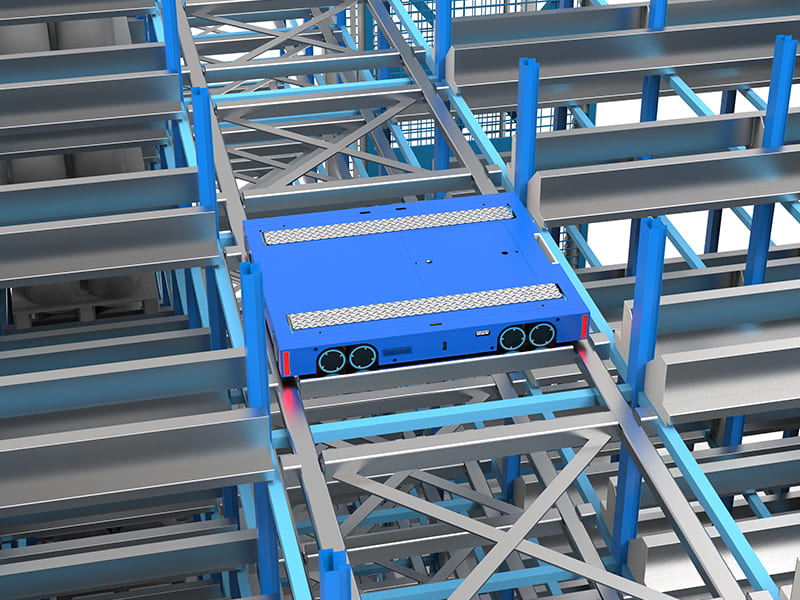

4 Way Pallet Shuttle System is an advanced automated storage solution designed to handle palletized goods with high efficiency. Using four-directional movement technology to move freely through storage lanes, achieving much higher density…

An Automated Intralogistics system efficiently transports goods within the warehouse without the need for manual labor, enhancing speed accuracy, and overall productivity

The program manages the entire warehouse from receiving and storing to picking and shipping. It reduces stock issues, tracks inventory, and provides actionable insights for efficient operations.