Preventive Maintenance Services for Automated Warehouse Systems We provide preventive maintenance services for government and state enterprises, including the Tobacco Factory under the Ministry of Finance. Our team consists of specialized engineers with over 10 years of experience in implementing automated warehouse systems, trained to handle every aspect of system maintenance. Each service includes a detailed report, allowing clients to monitor usage, servicing, parts replacement, maintenance, and inspections for potential equipment issues. This covers critical components such as 28+ conveyor chains, large electrical panels, 4 automated stacker cranes, and over 36 lifts. Our team also provides targeted recommendations, analyzes system performance, and identifies solutions to minimize downtime and maintain optimal operational efficiency.

CONVEYOR CHAIN

28

Units

table lift

36

Units

Electric cabinet

2

Units

Auto Crane

4

Units

Capacity

248

Locations

Location

U-thai

Ayutthaya

We are a System Integrator team importing world-class machinery from leading global brands, with over 10 years of experience in Automated Storage and Retrieval Systems (AS/RS). Our one-stop service is delivered by skilled Thai engineers and programmers specializing in WCS/WMS software and PLC hardware. Every project is supervised by our in-house engineering team ensuring seamless integration, precision, and reliability from start to finish.

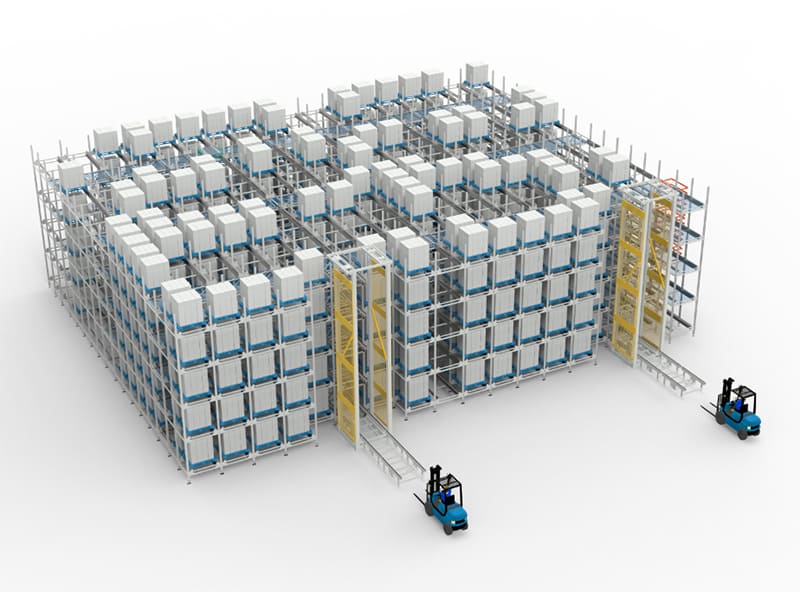

Automated Storage and Retrieval System (AS/RS) consists of racking structures designed for both horizontal and vertical storage, with multiple tiers to maximize space utilization. The system is operated by automated cranes or machines (SRM) that handle…

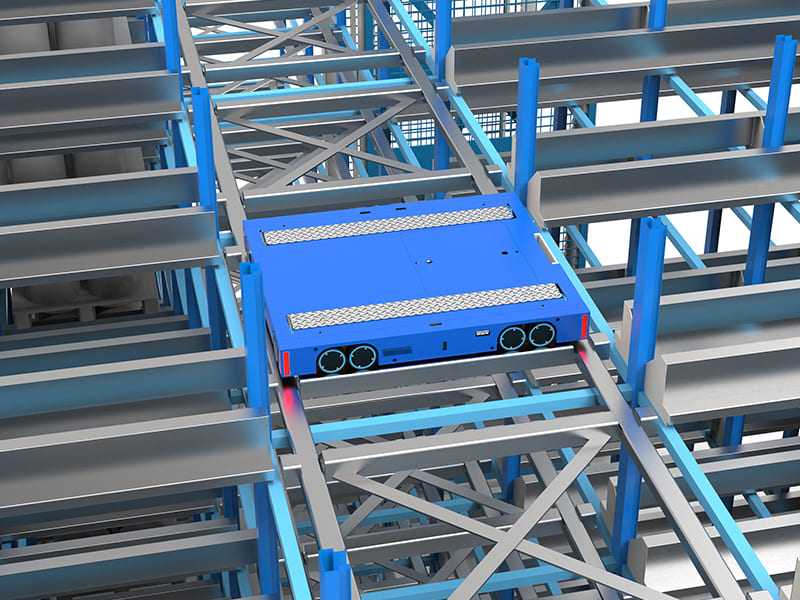

4 Way Pallet Shuttle System is an advanced automated storage solution designed to handle palletized goods with high efficiency. Using four-directional movement technology to move freely through storage lanes, achieving much higher density…

An Automated Intralogistics system efficiently transports goods within the warehouse without the need for manual labor, enhancing speed accuracy, and overall productivity

The program manages the entire warehouse from receiving and storing to picking and shipping. It reduces stock issues, tracks inventory, and provides actionable insights for efficient operations.