Suitable for warehouses that manage the storage of goods in pallet form, large-sized items, with weight and space constraints. The operation of the automatic crane, unit-load, is divided as follows:

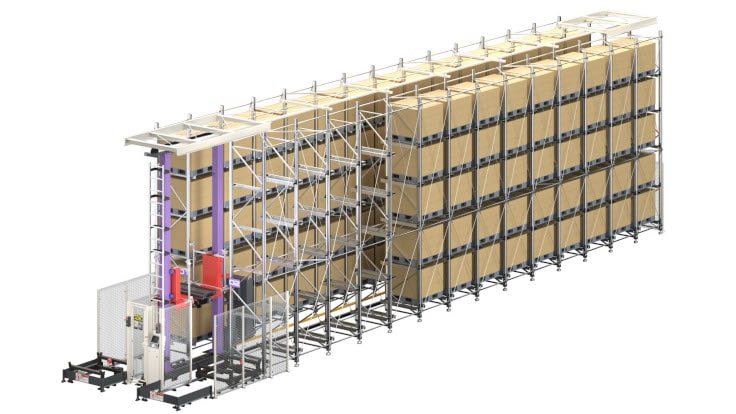

For products stored in pallet racks (pallet) with a single row deep, the system efficiently handles the retrieval and storage of goods both inbound and outbound quickly. By extending or retracting the length of the crane’s telescopic fork, it can pick up or place pallets. This makes it ideal for storing products that rotate in and out on a First In, First Out (FIFO) basis, large and heavy items stored on pallets, and warehouses with limited storage space only.

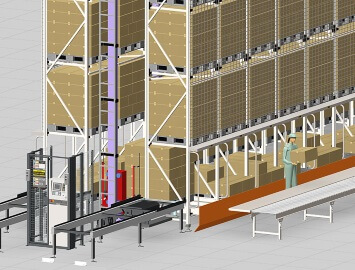

For products stored in pallet racks with a depth of 2 rows, the system handles the retrieval and storage of goods both inbound and outbound quickly. Similar to single-deep racks, it uses the length of the crane’s telescopic fork, but it can only reach the second storage slot. Therefore, the crane needs to be more robust. Although the operation may be slower, this type of crane can store up to twice as many items compared to single-deep racks, given the same area.

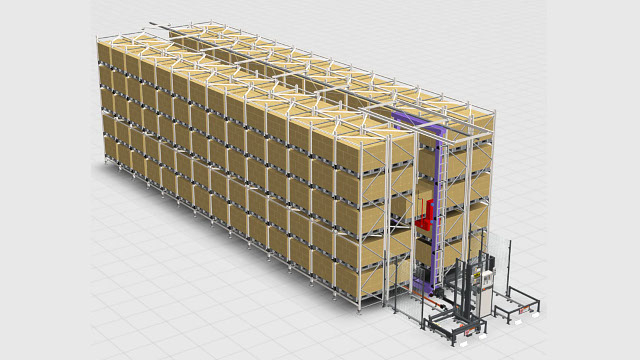

For products stored in pallet racks with a depth of 3 rows or more, a shuttle vehicle is required to handle the transportation of pallets. This setup allows for storing a large quantity of items in a limited space. The products are categorized into different types with few SKUs, but each SKU can be delivered in large quantities at a time.

For products stored in pallet racks with depth, and using a shuttle vehicle to handle the transportation of pallets, the shuttle can move in all four directions—left, right, up, and down. This capability significantly enhances the efficiency of goods handling.

We provide complete warehouse management solutions tailored to every business's needs.