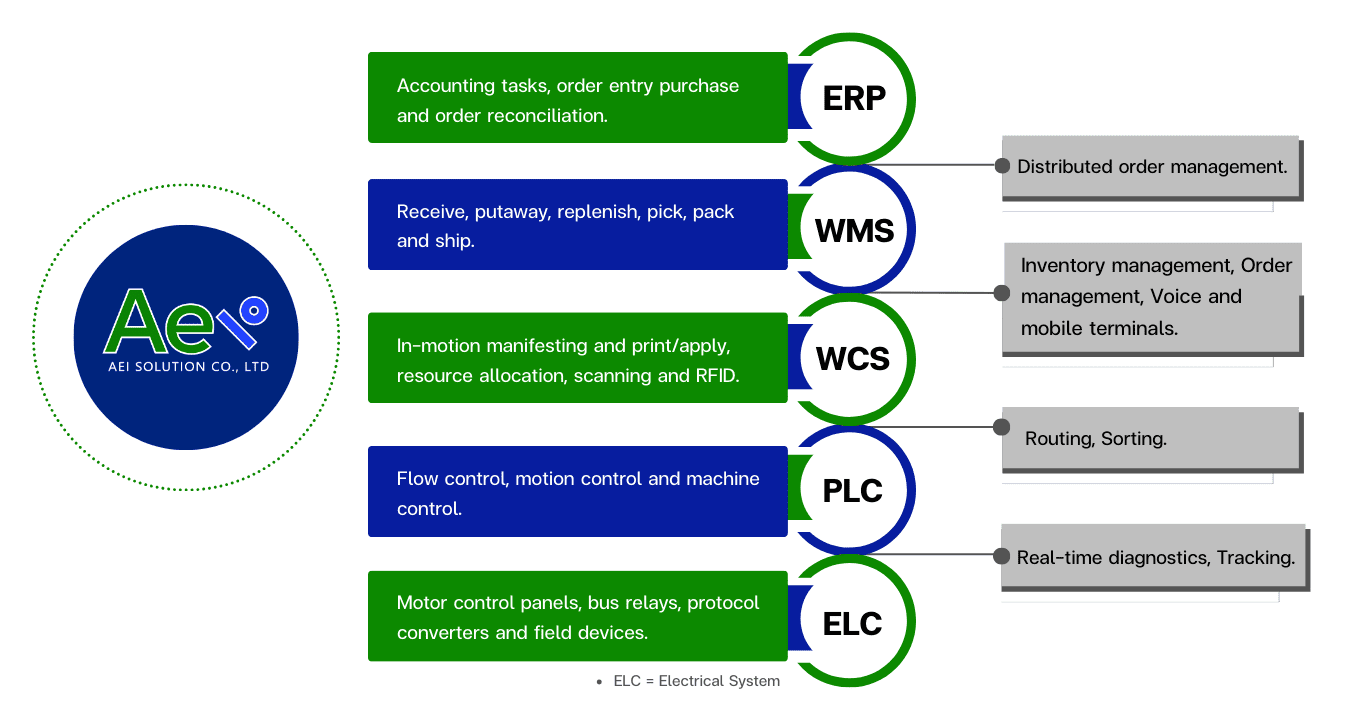

The software system was developed for managing general warehouse operations, including receiving, storing, and

distributing goods. The system consists of three main modules: Receiving, Storage, and Delivery.

Not every warehouse needs to use a WMS (Warehouse Management System), but it is certain that any warehouse implementing

a WMS will undoubtedly benefit from using the software.

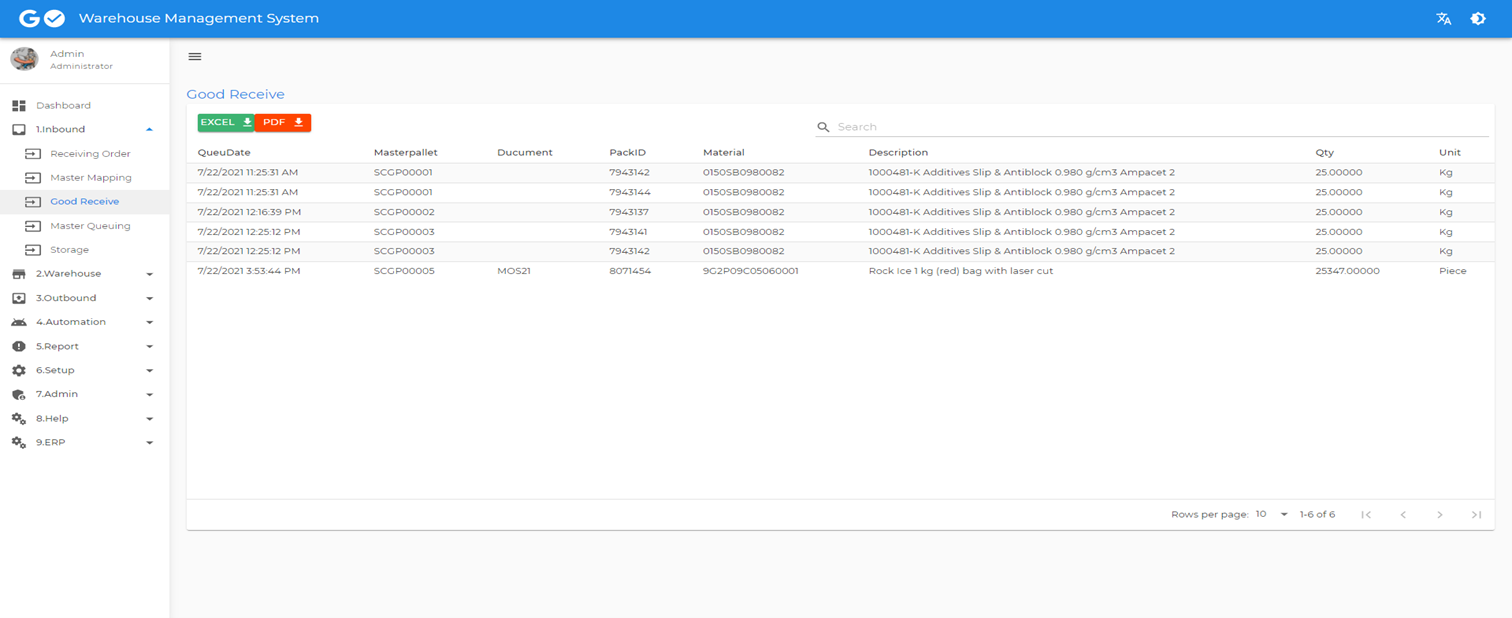

The receiving process for goods or raw materials into the warehouse involves:

The storage process for goods or raw materials, following the receiving, inspection, and labeling stages, involves:

The picking process for preparing items for shipment involves:

The picking process for preparing items for shipment involves:

For utilizing a Warehouse Management System (WMS), the equipment can be categorized as follows:

To connect all devices for transmitting data to the server and receiving processed information back, data transmission equipment comes in two types: wired and wireless.

For installing a Warehouse Management System (WMS), the specifications of the equipment, including speed and storage capacity, depend on the volume of data that needs to be managed within the system.